Durable Stainless Steel BBQ Grill Mesh for Ultimate Grilling Experience

By:Admin

The {Company} is a well-established company that specializes in providing top-notch outdoor cooking equipment for both residential and commercial use. They have built a strong reputation in the industry for producing innovative and high-quality products that meet the needs of their customers.

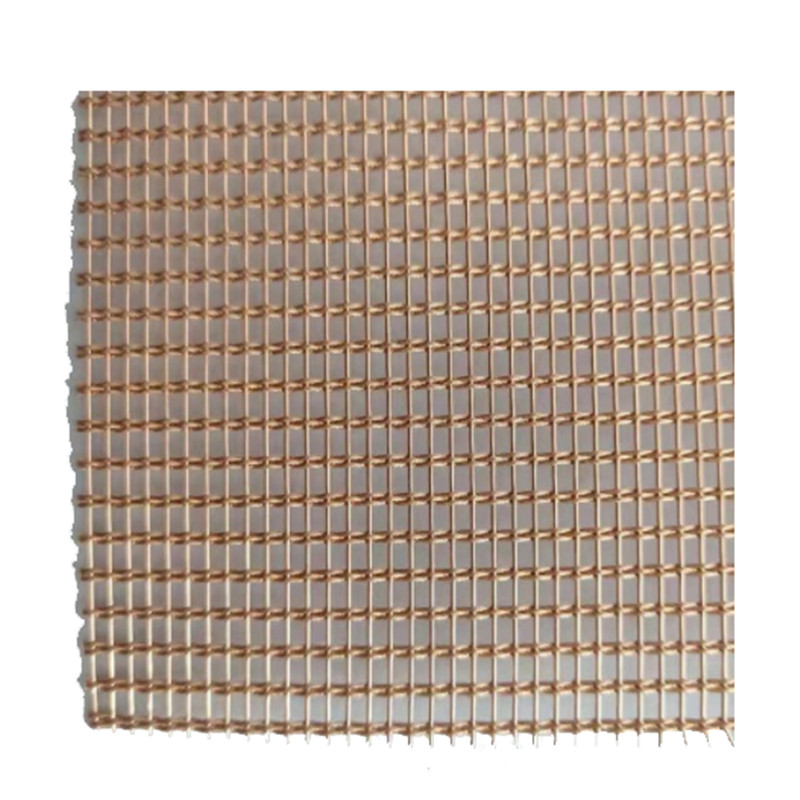

The Stainless Steel BBQ Grill Mesh is a reflection of the {Company}’s commitment to providing their customers with the best possible outdoor cooking experience. This new product is made from premium quality stainless steel, which is known for its durability and resistance to rust and corrosion. This ensures that the grill mesh will be able to withstand the high heat and outdoor elements, making it a long-lasting addition to any outdoor cooking setup.

One of the key features of the Stainless Steel BBQ Grill Mesh is its versatile design. The mesh is designed to be used on a variety of grills, including gas, charcoal, and electric grills, making it a versatile option for customers with different cooking setups. Additionally, the mesh is designed to be non-stick, making it easy to clean and maintain. This feature is particularly valuable for those who enjoy cooking a variety of foods on their grill, as it allows for easy flipping and turning of foods without the risk of sticking.

In addition to its practical features, the Stainless Steel BBQ Grill Mesh is also designed with safety in mind. The mesh is constructed with small, tight grids to ensure that smaller food items such as vegetables and seafood do not fall through the grates and cause flare-ups. This feature not only enhances the safety of cooking on the grill but also allows for a wider variety of foods to be cooked on the grill without the risk of them falling through the grates.

The {Company} has also paid special attention to the design and aesthetics of the Stainless Steel BBQ Grill Mesh. The mesh is made with a sleek and modern design that is sure to complement any outdoor cooking setup. The company understands that the appearance of outdoor cooking equipment is just as important as its functionality, and they have ensured that the grill mesh is visually appealing and well-made.

In order to accommodate the diverse needs of their customers, the {Company} offers the Stainless Steel BBQ Grill Mesh in a variety of sizes, allowing customers to select the option that best fits their grilling needs. Whether customers are cooking for a small family or hosting a large outdoor gathering, there is a grill mesh size available to meet their specific requirements.

The release of the Stainless Steel BBQ Grill Mesh reflects the {Company}’s dedication to providing their customers with high-quality outdoor cooking equipment that enhances their cooking experience. The company has a long-standing commitment to excellence and innovation, and this new product is a clear demonstration of their ongoing efforts to meet the needs of their customers.

Overall, the Stainless Steel BBQ Grill Mesh is a valuable addition to the {Company}’s lineup of outdoor cooking equipment. With its premium quality construction, versatile design, safety features, and modern aesthetic, the grill mesh is sure to be a popular choice for customers looking to elevate their outdoor cooking experience. Whether customers are grilling up steaks, seafood, vegetables, or anything in between, the Stainless Steel BBQ Grill Mesh is designed to deliver exceptional results and provide customers with a reliable and long-lasting grilling surface.

Company News & Blog

Discover the Benefits of Using Knitted Copper Mesh for Various Applications

Title: Innovative Copper Mesh Technology Takes Center Stage in Industrial ApplicationsIntroduction:In an era of rapid technological advancements, the utilization of innovative materials for various industrial applications has become paramount. One such revolutionary material is Knitted Copper Mesh, a cutting-edge solution that promises to revolutionize multiple industries. This article highlights the significant features and applications of this remarkable material while shedding light on the company responsible for its development.The Growth of Knitted Copper Mesh:With the increasing demand for efficient and sustainable solutions, Knitted Copper Mesh has emerged as a breakthrough material in recent years. Boasting a unique combination of flexibility and durability, this knitted mesh has a wide range of applications across multiple industries.Features of Knitted Copper Mesh:Knitted Copper Mesh stands out due to its remarkable characteristics, making it a versatile and sought-after material for industrial use. Its key features include:1. Conductivity: With exceptional electrical conductivity, the copper mesh ensures effective transmission of electrical signals, making it ideal for use in electronics, telecommunications, and electrical applications.2. Durability: The knitted copper structure provides exceptional durability, ensuring the material remains intact even in demanding conditions, making it suitable for long-term and high-stress applications.3. Heat Resistance: Knitted Copper Mesh exhibits excellent heat resistance properties, making it reliable in high-temperature environments, such as thermal insulation systems, industrial ovens, and exhaust systems.4. Anti-Microbial Properties: The inherent anti-microbial properties of copper make the knitted copper mesh an excellent choice for applications in healthcare settings, food processing facilities, and sterile environments.Industrial Applications of Knitted Copper Mesh:1. Electronics Industry: Knitted Copper Mesh finds extensive use in the electronics industry due to its superior conductivity. It is widely employed in devices such as smartphones, tablets, computers, and various other electronic components, ensuring efficient signal transmission and reducing electromagnetic interference.2. Filtration Systems: The flexibility and durability of Knitted Copper Mesh make it an ideal material for filtration systems. Its intricate knitted structure allows for efficient air and fluid filtration, making it suitable for applications in water and air purification systems, HVAC systems, and oil or gas filtration.3. Energy Generation and Storage: The high electrical conductivity of the copper mesh is advantageous in applications related to the generation and storage of energy. It is widely used in batteries, solar panels, and fuel cells, ensuring efficient energy transfer and improved overall performance.4. Automotive Industry: Knitted Copper Mesh is gaining traction in the automotive industry due to its capacity to conduct electricity and withstand extreme conditions. It is utilized in various applications, including electrical wiring, engine components, and exhaust systems.Company Background and Expertise:Insert Company Introduction Here. Provide a brief overview of the company responsible for the development and production of Knitted Copper Mesh. Highlight the expertise, technology, and commitment to innovation that sets the company apart from its competitors.Conclusion:Knitted Copper Mesh has emerged as a game-changing material, offering unique properties that cater to the evolving needs of numerous industries. With its exceptional electrical conductivity, durability, heat resistance, and anti-microbial features, this innovative material presents diverse applications across the electronics, filtration, energy, and automotive sectors. With the continuous drive for innovation and commitment to excellence by companies, including [Company Name], the future of industrial applications with Knitted Copper Mesh looks promising, ensuring more efficient, sustainable, and reliable solutions.

Durable and Versatile Brass Mesh Fabric for Various Applications

20micron Brass Mesh Fabric Provides High-Quality Solutions for Various IndustriesAs an industry leader in the production and distribution of high-quality brass mesh fabric, the company has established itself as a premier provider of innovative solutions for a wide range of applications. With a commitment to excellence and customer satisfaction, the company has earned a reputation for delivering superior products that meet the diverse needs of its clients.The 20micron brass mesh fabric offered by the company is known for its exceptional quality, durability, and versatility. Made from high-grade brass material, the mesh fabric is designed to withstand the harshest conditions and deliver outstanding performance in various industrial and commercial settings. Whether used for filtration, screening, or decorative purposes, the brass mesh fabric is proven to be a reliable and cost-effective solution for a wide range of applications.One of the key advantages of the 20micron brass mesh fabric is its high level of precision and accuracy. The fabric is meticulously crafted to ensure uniformity in mesh size, thickness, and overall quality, making it an ideal choice for demanding applications that require reliable and consistent performance. This level of precision and attention to detail sets the company's brass mesh fabric apart from the competition, and has earned the trust and satisfaction of countless customers worldwide.In addition to its exceptional quality, the 20micron brass mesh fabric is also known for its versatility and adaptability. With a wide range of mesh sizes and configurations to choose from, the fabric can be customized to meet the specific requirements of different industries and applications. From industrial filtration and separation to architectural and design projects, the brass mesh fabric offers a flexible and customizable solution that can be tailored to suit the unique needs of each client.Furthermore, the 20micron brass mesh fabric is backed by the company's commitment to sustainability and environmental responsibility. Made from recyclable and eco-friendly materials, the fabric is designed to minimize environmental impact and support sustainable practices. This focus on sustainability not only reflects the company's dedication to ethical and responsible business practices, but also ensures that customers can confidently choose the brass mesh fabric as a sustainable and eco-friendly solution for their projects.With a strong emphasis on quality, performance, and customer satisfaction, the company has positioned itself as a trusted partner for businesses and industries seeking reliable and high-quality brass mesh fabric solutions. By continuously investing in research, development, and innovation, the company remains at the forefront of the industry, offering cutting-edge products and solutions that are designed to meet the evolving needs of its clients.In conclusion, the 20micron brass mesh fabric offered by the company is a testament to its commitment to excellence and innovation. With its exceptional quality, precision, versatility, and sustainability, the fabric has become the go-to choice for businesses and industries seeking high-performance solutions for a wide range of applications. As the company continues to lead the way in the industry, it remains dedicated to providing superior products and services that exceed the expectations of its customers, and contribute to the success and growth of its clients around the world.

Benefits of Using Interlayer Metal Mesh in Laminated Glass

Interlayer Metal Mesh in Laminated Glass Revolutionizes Safety and AestheticsLaminated glass is a crucial component in modern architecture and automotive industries, providing both safety and aesthetic benefits. Traditionally, laminated glass has been produced by sandwiching a layer of polyvinyl butyral (PVB) between two or more sheets of glass. While this method has been effective in increasing the strength and durability of glass, a new innovation in the form of interlayer metal mesh has revolutionized the way in which laminated glass is produced.[Company Name], a leading manufacturer in the glass industry, has introduced a groundbreaking technology that incorporates a layer of metal mesh within laminated glass. This innovative approach enhances the strength and safety features of the glass, while also introducing a new level of design possibilities. The interlayer metal mesh provides additional reinforcement to the glass, making it highly resistant to impact, forced entry, and extreme weather conditions. This makes it particularly suitable for high-security applications in both architectural and automotive settings.The interlayer metal mesh also introduces exciting design opportunities, allowing for customization and creativity in the production of laminated glass. The metal mesh can be tailored to various patterns, shapes, and colors, adding a new dimension to the aesthetic appeal of the glass. This innovative approach to laminated glass production is poised to revolutionize the way in which glass is used in architectural designs, interior decor, and automotive applications.[Company Name] has leveraged its expertise and state-of-the-art manufacturing facilities to develop this cutting-edge technology, positioning itself as a pioneer in the glass industry. With a strong focus on research and development, the company has been able to push the boundaries of glass production, introducing new materials and techniques to meet the evolving needs of its customers. The introduction of the interlayer metal mesh in laminated glass is a testament to [Company Name]'s commitment to innovation and excellence.In addition to its safety and design advantages, the interlayer metal mesh in laminated glass also offers environmental benefits. The enhanced durability and strength of the glass result in a longer lifespan, reducing the need for frequent replacements and contributing to sustainability efforts. This aligns with [Company Name]'s dedication to environmental responsibility and sustainable manufacturing practices.The introduction of this groundbreaking technology has generated significant interest and excitement within the glass industry. Architects, designers, and engineers are eager to explore the possibilities offered by the interlayer metal mesh in laminated glass, envisioning new and innovative applications for this versatile material. The enhanced safety features make it an attractive choice for high-traffic areas, public spaces, and buildings in regions prone to severe weather conditions. The design flexibility further expands the potential uses of this innovative laminated glass, opening doors to a new era of creativity and expression in architectural and automotive design.As [Company Name] continues to spearhead advancements in the glass industry, the introduction of the interlayer metal mesh in laminated glass stands out as a significant milestone. This revolutionary technology has redefined the possibilities for safety, aesthetics, and sustainability in glass production, setting a new standard for the industry as a whole. With its dedication to innovation and excellence, [Company Name] is well-positioned to lead the way in the continued evolution of laminated glass and its applications across various sectors.In conclusion, the incorporation of interlayer metal mesh in laminated glass represents a seismic shift in the glass industry, offering unprecedented levels of strength, safety, and design capabilities. [Company Name]'s pioneering efforts in developing and introducing this cutting-edge technology have positioned it as a leader in the field, setting the stage for a new era of innovation and creativity in glass production. As this revolutionary material gains traction in architectural and automotive applications, its impact will be felt far and wide, shaping the future of design and safety in the use of glass.

Durable Cut Resistant Mesh Chain Steel Gloves for Meat Handling

Cut Resistant Mesh Chain Meat Steel Gloves have become a popular choice for individuals working in the meat industry, as they provide protection against sharp tools and machinery. This innovative product is designed to keep workers safe while they handle raw meat, preventing accidental cuts and injuries.The gloves are made from high-quality stainless steel mesh, providing excellent cut resistance and durability. They are designed to fit comfortably on the hands, allowing for maximum dexterity and flexibility while working. The gloves are also easy to clean and maintain, making them an ideal choice for busy meat processing environments.In addition to their practical benefits, Cut Resistant Mesh Chain Meat Steel Gloves also comply with food safety regulations, making them a reliable choice for food industry workers. They are designed to prevent contamination and maintain hygiene standards, ensuring that the meat processing environment remains clean and safe for workers and consumers.{Company Name} has been at the forefront of producing high-quality safety equipment for the food industry for over 20 years. The company prides itself on its commitment to providing innovative and reliable products that meet the evolving needs of its customers. With a focus on quality and safety, {Company Name} has become a trusted name in the industry, offering a wide range of products that cater to the specific requirements of food processing and handling.The introduction of Cut Resistant Mesh Chain Meat Steel Gloves is a testament to {Company Name}'s dedication to providing effective solutions for safety in the meat industry. By combining their expertise in safety equipment with the latest technology and materials, the company has developed a product that is dependable and practical for workers in meat processing facilities."We are proud to introduce our Cut Resistant Mesh Chain Meat Steel Gloves, which are designed to provide maximum protection and comfort for workers in the meat industry," says {Company Name} spokesperson. "We understand the potential risks that come with handling sharp tools and machinery in this environment, and our goal is to provide a reliable solution that ensures the safety of our customers."The gloves have been well-received by workers in the meat industry, who have praised their durability and effectiveness in providing protection against cuts and injuries. Many have also appreciated the comfortable fit and flexibility of the gloves, which allow for easy movement and dexterity while working.{Company Name} is dedicated to providing ongoing support and education to its customers, ensuring that they are fully informed about the proper use and maintenance of the gloves. This includes providing training on how to effectively clean and care for the gloves, as well as offering guidance on when to replace them to ensure continued safety and protection.As the meat industry continues to evolve and grow, the demand for reliable safety equipment such as Cut Resistant Mesh Chain Meat Steel Gloves is expected to increase. With a commitment to innovation and quality, {Company Name} is well-positioned to continue meeting the needs of workers in this industry, providing them with the protection and peace of mind they deserve.In conclusion, Cut Resistant Mesh Chain Meat Steel Gloves have proven to be a valuable addition to the safety equipment available for workers in the meat industry. With their reliable protection, comfort, and compliance with food safety regulations, these gloves are a practical choice for meat processing facilities. By introducing this innovative product, {Company Name} has once again demonstrated its commitment to providing effective solutions for safety in the food industry, further solidifying its reputation as a trusted provider of quality safety equipment.

Decorative Wire Mesh Laminated in Glass for Stunning Interior Design

Glass Laminated Decorative Wire Mesh: Enhancing Aesthetics and FunctionalityWire mesh has been a longstanding component in architectural and interior design, offering both aesthetic appeal and functional benefits. In recent years, the integration of glass laminates with wire mesh has taken the design world by storm, offering a unique blend of transparency, durability, and artistic expression. One company that has been at the forefront of this innovation is (Company Name), a leading manufacturer of architectural and decorative wire mesh products.Founded in (year), (Company Name) has established itself as a pioneering force in the wire mesh industry, continually pushing the boundaries of design and functionality. With a focus on quality craftsmanship and innovative solutions, the company has garnered a reputation for its extensive range of wire mesh products, including woven, welded, and perforated variations. However, it is their glass laminated decorative wire mesh that has been making waves in the design community.Through a meticulous process of laminating high-quality glass with specialty wire mesh, (Company Name) has been able to create a product that seamlessly combines the strength and stability of mesh with the transparency and elegance of glass. This unique combination opens up a world of possibilities in architectural and interior design, allowing for the creation of stunning partitions, facades, balustrades, and cladding systems that are as functional as they are visually striking.The applications of glass laminated decorative wire mesh are vast, with its use extending to commercial, residential, and public spaces. The product offers a balance of privacy and openness, allowing natural light to filter through while maintaining a sense of separation and security. This makes it an ideal choice for creating visually impactful yet functional elements within a space, whether it be for a luxury hotel, a corporate office, or a residential development.What sets (Company Name) apart in the industry is not just their innovative product offerings, but also their commitment to customization and collaboration. Understanding that each project comes with its own unique set of requirements, the company works closely with architects, designers, and contractors to develop tailor-made solutions that meet specific design and performance criteria. This collaborative approach has led to the successful integration of glass laminated decorative wire mesh in a wide range of architectural projects around the world.In addition to their dedication to innovation and collaboration, (Company Name) places a strong emphasis on sustainability and environmental responsibility in their manufacturing processes. By utilizing high-quality, recyclable materials and optimizing production techniques, they strive to minimize their environmental impact while delivering products that are built to last.Looking ahead, (Company Name) continues to drive the evolution of decorative wire mesh solutions, with a focus on pushing the boundaries of design, performance, and sustainability. As the demand for unique, versatile, and visually captivating architectural elements grows, the integration of glass laminated decorative wire mesh is poised to play an increasingly pivotal role in the future of design and construction.In conclusion, (Company Name) stands as a testament to the power of innovation and collaboration in the architectural and design industry. Their glass laminated decorative wire mesh embodies a perfect union of form and function, offering a versatile and visually striking solution for architects, designers, and builders. As the company looks to the future, their dedication to pushing the boundaries of design and sustainability ensures that they will continue to be a driving force in the evolution of architectural wire mesh products.

Versatile Mesh Options for Liquid or Gas Applications

In the world of industrial manufacturing, the efficiency and reliability of filtration systems are crucial for ensuring the quality of the final product. That's where the innovative mesh for liquid or gas comes into play, providing a cutting-edge solution for companies in need of superior filtration technology.With a focus on delivering high-quality mesh products, {Company Name} has established itself as a leading provider of filtration solutions for a wide range of industrial applications. The company's dedication to research and development has led to the creation of a diverse portfolio of mesh products, catering to the specific needs of its clients across various industries.The mesh for liquid or gas offered by {Company Name} is designed to provide effective filtration for a variety of fluids and gases, ensuring that impurities and contaminants are effectively removed from the process stream. This not only helps to improve the overall quality of the final product but also contributes to the reliability and efficiency of the manufacturing process.One of the key advantages of {Company Name}'s mesh for liquid or gas is its exceptional durability and longevity. The company utilizes advanced materials and manufacturing techniques to ensure that its mesh products can withstand the harshest of operating conditions, making them an ideal choice for demanding industrial environments.Furthermore, {Company Name} takes pride in its ability to customize mesh products to meet the specific requirements of its clients. Whether it's a unique mesh size, material composition, or structural configuration, the company's team of experts works closely with its clients to develop tailored solutions that address their individual filtration challenges.In addition to its commitment to product excellence, {Company Name} places a strong emphasis on sustainability and environmental responsibility in its manufacturing processes. The company strives to minimize its environmental footprint by adhering to strict quality and environmental management standards, ensuring that its mesh products are not only efficient but also eco-friendly.{Company Name} also stands out for its dedication to customer service and support. The company's team of professionals is readily available to provide technical expertise, assistance with product selection, and ongoing support to ensure that its clients achieve optimal results with their filtration systems.In the fast-paced world of industrial manufacturing, staying ahead of the competition is essential. By offering innovative and reliable mesh for liquid or gas, {Company Name} continues to demonstrate its commitment to helping its clients achieve their production goals with confidence and efficiency. As the industry evolves, {Company Name} remains at the forefront, continuously developing new solutions to meet the ever-changing needs of the manufacturing sector.In conclusion, the mesh for liquid or gas provided by {Company Name} represents a testament to the company's dedication to excellence, innovation, and customer satisfaction. With a focus on quality, customization, sustainability, and support, {Company Name} has solidified its position as a trusted partner for companies seeking top-tier filtration solutions. As the demand for advanced filtration technology continues to grow, {Company Name} stands ready to meet the challenge, driving the industry forward with its cutting-edge mesh products.With a steadfast commitment to quality and a forward-thinking approach, {Company Name} is not only meeting the needs of the present but also shaping the future of industrial filtration. As the company continues to expand its product offerings and reach new milestones, one thing remains certain: {Company Name} will remain a driving force in the evolution of filtration technology for years to come.

High-Quality Sintered Filter for Optimal Filtration Performance

Sintered Filter Company X Leads the Way in Advanced Filtration TechnologyCompany X is a leading manufacturer of sintered filters, known for their innovative and high-quality filtration products. With a strong commitment to research and development, Company X has earned a reputation for producing cutting-edge solutions for a wide range of industrial applications.Sintered filters are a type of porous metal media that offers superior filtration performance compared to traditional filter materials. They are widely used in industries such as oil and gas, automotive, pharmaceuticals, and chemical processing, where high levels of filtration efficiency are critical.The unique structure of sintered filters allows for the removal of contaminants from a wide range of fluids, gases, and solids, making them an essential component in many industrial processes. Company X's sintered filters are designed to withstand high temperatures, corrosive environments, and high-pressure conditions, ensuring reliable and consistent filtration performance.One of the key advantages of Company X's sintered filters is their exceptional durability and long service life. They are designed to withstand harsh operating conditions and require minimal maintenance, making them a cost-effective solution for many industrial applications.Company X's commitment to innovation and continuous improvement has led to the development of a wide range of sintered filter products that can meet the diverse needs of their customers. Whether it's a standard sintered filter or a custom-designed solution, Company X has the expertise and capabilities to deliver high-performance filtration products that exceed the industry's expectations.In addition to their advanced filtration technology, Company X also provides comprehensive technical support and engineering services to assist their customers in finding the right filtration solution for their specific requirements. Their team of experts has the knowledge and experience to help customers optimize their filtration processes and achieve maximum performance and efficiency.Furthermore, sustainability is also a core value for Company X, and their sintered filters are designed with the environment in mind. By providing efficient filtration solutions, Company X helps their customers reduce waste and minimize the environmental impact of their operations.Company X is also committed to maintaining the highest standards of quality and reliability in their products. They adhere to strict manufacturing processes and quality control procedures to ensure that every sintered filter that leaves their facility meets the highest standards of performance and reliability.As a testament to their dedication to quality and customer satisfaction, Company X has been recognized with various industry certifications and awards for their outstanding performance in the field of filtration technology.In conclusion, Company X is a leading force in the advancement of sintered filter technology. With their unwavering commitment to innovation, quality, and customer satisfaction, Company X continues to lead the way in delivering high-performance filtration solutions to industries around the world. Whether it's for standard applications or custom-designed solutions, customers can rely on Company X's sintered filters to meet their most demanding filtration requirements.

High-Quality Sintered Felt Filter for Effective Filtration

Sintered Felt Filter is Making Waves in the Filtration IndustryWith the increasing demand for higher quality filtration systems in various industries, the need for reliable and efficient filter solutions has never been greater. In response to this demand, one company has been making waves in the filtration industry with their innovative sintered felt filter technology.Founded in 2005, the company has been at the forefront of developing and manufacturing high-quality filtration products for a wide range of applications. Their sintered felt filter is a testament to their dedication to producing innovative and effective solutions for their customers.The sintered felt filter is a unique and advanced filtration technology that offers exceptional performance and longevity. It is made from a porous metal material that is sintered at high temperatures to create a rigid and durable structure. This process results in a filter that is capable of withstanding high temperatures, corrosive chemicals, and high pressure, making it ideal for demanding industrial applications.One of the key advantages of the sintered felt filter is its superior filtration efficiency. The porous structure of the filter allows for the efficient removal of solid particles and contaminants from liquids and gases, ensuring a clean and pure end product. This level of filtration performance is crucial for industries such as oil and gas, chemical processing, and wastewater treatment, where product quality and safety are paramount.In addition to its exceptional filtration capabilities, the sintered felt filter also offers a longer service life compared to traditional filter media. Its robust construction and resistance to harsh operating conditions mean that it can continue to deliver reliable filtration performance over an extended period, reducing the need for frequent filter replacements and maintenance.Furthermore, the sintered felt filter can be custom-engineered to meet specific application requirements. This flexibility enables the company to provide tailored filtration solutions that address the unique needs of their customers, ensuring optimal performance and cost-effectiveness.The company's commitment to quality and innovation has cemented its reputation as a trusted provider of filtration solutions. Their sintered felt filter has been widely acclaimed for its exceptional performance, reliability, and versatility, making it a preferred choice for discerning customers across various industries.In addition to their sintered felt filter, the company offers a comprehensive range of filtration products, including sintered mesh filters, pleated filters, and filter cartridges. These products are designed to meet the diverse needs of modern industrial applications, providing reliable and efficient solutions for even the most challenging filtration requirements.With a strong focus on research and development, the company continues to push the boundaries of filtration technology, striving to develop new and innovative products that address the evolving needs of their customers. Their ongoing investment in advanced manufacturing techniques and state-of-the-art equipment ensures that they remain at the forefront of the filtration industry, delivering cutting-edge solutions that set new standards for performance and reliability.As the demand for high-quality filtration solutions continues to grow, the company is poised to play a pivotal role in shaping the future of the industry. With their unwavering commitment to excellence and a track record of delivering superior filtration products, they are well-positioned to meet the evolving needs of their customers and contribute to the advancement of filtration technology.In conclusion, the sintered felt filter from this innovative company has emerged as a game-changer in the filtration industry. Its superior performance, longevity, and flexibility make it a standout choice for industries that demand the highest standards of filtration. With a solid reputation for innovation and excellence, the company is set to take the filtration industry to new heights, providing customers with reliable and effective solutions for their critical filtration needs.

Durable and Versatile Wire Mesh for Various Applications

Wire Mesh Solutions: A Pioneering Solution for Industrial ApplicationsWire mesh has been a crucial component in a wide range of industrial applications, providing strength, durability, and versatility. {Company Name}, a leading manufacturer of wire mesh products, has been at the forefront of producing high-quality wire mesh solutions for a variety of industries.{Company Name} was founded with the vision of providing innovative and reliable wire mesh products to meet the evolving needs of the industrial market. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, the company has established itself as a trusted provider of wire mesh solutions.The company's comprehensive range of wire mesh products includes woven wire mesh, welded wire mesh, expanded metal mesh, and perforated metal mesh, catering to diverse applications such as filtration, separation, reinforcement, and protection. {Company Name} is committed to delivering customized solutions to meet the specific requirements of its clients, ensuring high performance and efficiency in their industrial processes.One of the key factors that set {Company Name} apart from its competitors is its focus on innovation and technology. The company continuously invests in research and development to enhance the design, quality, and performance of its wire mesh products. By leveraging cutting-edge manufacturing techniques and materials, {Company Name} has been able to provide advanced wire mesh solutions that deliver superior performance and reliability.Moreover, {Company Name} places a strong emphasis on quality control and testing to ensure that its wire mesh products meet the highest standards of durability and functionality. The company's commitment to quality is reflected in its ISO certification and compliance with industry regulations, giving customers confidence in the reliability and performance of its wire mesh solutions.In addition to its dedication to product quality, {Company Name} is also recognized for its customer-centric approach. The company works closely with its clients to understand their unique requirements and provide tailored wire mesh solutions that address their specific needs. Whether it's designing custom wire mesh configurations or providing expert technical support, {Company Name} strives to exceed its customers' expectations and build long-lasting partnerships.{Company Name} serves a wide range of industries, including construction, mining, agriculture, petrochemical, and automotive, demonstrating the versatility and applicability of its wire mesh products. From heavy-duty industrial applications to intricate architectural designs, {Company Name} has the expertise and capabilities to deliver wire mesh solutions that meet the demands of diverse sectors.Looking ahead, {Company Name} remains committed to driving innovation and excellence in the field of wire mesh solutions. The company continues to push the boundaries of wire mesh technology, exploring new materials, designs, and applications to enhance the performance and functionality of its products. With a focus on sustainability and environmental responsibility, {Company Name} also seeks to develop eco-friendly wire mesh solutions that minimize the impact on the planet.In conclusion, wire mesh solutions have become an integral part of industrial processes, offering strength, durability, and versatility across a wide range of applications. {Company Name} has established itself as a leading provider of high-quality wire mesh products, driven by innovation, quality, and customer satisfaction. As industries continue to evolve and demand advanced wire mesh solutions, {Company Name} is well-positioned to continue its pioneering efforts in delivering cutting-edge products that meet the ever-changing needs of the industrial market.

Highly Durable Filter Cloth for Industrial Applications

Inconel Filter Cloth is a high-performance filtration material that is widely used in various industries for its superior corrosion and oxidation resistance. The Inconel Filter Cloth is made from a special alloy of nickel, chromium, and iron, which makes it extremely durable and capable of withstanding high temperatures and harsh environments. The unique properties of Inconel Filter Cloth make it an ideal choice for applications where traditional filter materials would fail.The company behind the Inconel Filter Cloth is a leading manufacturer of advanced filtration solutions for industrial and commercial use. With years of experience in the industry, the company has developed a reputation for producing high-quality filtration materials that meet the most stringent requirements of its customers. The Inconel Filter Cloth is just one of the many innovative products offered by the company, which also includes filter bags, cartridges, and other filtration equipment.The Inconel Filter Cloth is designed to provide exceptional filtration performance in a wide range of applications, including chemical processing, petrochemical, and oil and gas industries. Its superior resistance to corrosion and high temperatures makes it an ideal choice for filtering aggressive and corrosive fluids, as well as for applications where the filtration material is exposed to extreme temperatures. The Inconel Filter Cloth is also highly resistant to mechanical wear and tear, making it a cost-effective and long-lasting filtration solution for industrial and commercial use.One of the key advantages of using Inconel Filter Cloth is its ability to withstand high-velocity gas and liquid streams without compromising its filtration efficiency. This makes it an ideal choice for a wide range of high-flow filtration applications, where traditional filter materials would be prone to damage and clogging. The excellent structural integrity of Inconel Filter Cloth allows it to maintain its filtration performance even under high-pressure and high-temperature conditions, ensuring reliable and consistent filtration results.In addition to its exceptional performance, Inconel Filter Cloth is also easy to install and maintain, reducing downtime and maintenance costs for industrial and commercial operations. The company behind the Inconel Filter Cloth provides comprehensive technical support and after-sales service to ensure that its customers can maximize the benefits of this advanced filtration material. With its extensive expertise in filtration technology, the company can also provide customized solutions to meet the specific filtration needs of its customers, ensuring optimal performance and efficiency.The Inconel Filter Cloth is manufactured to the highest quality standards, utilizing advanced production techniques and quality control processes to ensure consistent and reliable performance. The company behind the Inconel Filter Cloth is committed to sustainability and environmental responsibility, ensuring that its production processes adhere to the highest environmental standards. This commitment to sustainability extends to the end of the product lifecycle, with the company offering recycling and disposal solutions for used filtration materials, further reducing the environmental impact of its products.Overall, the Inconel Filter Cloth offers a cutting-edge filtration solution for industrial and commercial applications, providing exceptional performance, durability, and reliability. With the backing of a leading manufacturer of advanced filtration solutions, the Inconel Filter Cloth is set to make a significant impact in the industry, offering a cost-effective and sustainable filtration solution for a wide range of applications. As the demand for high-performance filtration materials continues to grow, the Inconel Filter Cloth is well-positioned to meet the needs of the industry and deliver superior filtration performance for years to come.